Industrial packaging is achieving thrust due to ground-breaking packaging solutions and customization accessible for these, according to customers’ desires. The comprehensive industrial packaging market has been fragmented on the basis of type, material, product, and end-user industry. On the basis of packaging type, the overall market has been subdivisioned into unbending and bendable. On the basis of material, the worldwide market has been pigeonholed into metal, plastic, paper and wood.

The global industrial packaging market is anticipated to eyewitness noteworthy development, during the forecast period (2016-2022), owing to assorted factors such as growing requirement for packaging, high demand from food and beverages industry, stringent safety regulations, and technological advancements. Appropriate packaging for secure material handling, storeroom and shipping is needed across a range of applications, ranging from products of everyday use to industrial machinery. The order for industrial packaging is growing on account of increasing application in an assortment of industries such as chemicals, construction and infrastructure, oil and gas, petrochemicals, automotive, industrial machinery, food and beverages, agriculture and metal fabrication. The elevated input outlays and recycling and ecological apprehensions are the major confronts being phizoged by the global industrial packaging market, which are probable to restrain its escalation, during the project period.

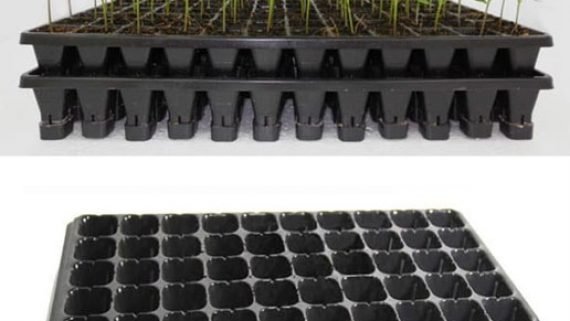

With regards to the renovation of apparatus and instrument, the desire for expedient storeroom and management of raw, semi-finished and finished materials have lifted up.. These circumstances have led to modernization in the invent of packaging of industrial trays across the foremost global manufacturers. We manufacture bearing tray, valve packing tray, engineering small parts tray, hardware packing tray, tools tray and valve packaging tray. Spangle propack posses huge range of machinery and owns mould making manufacturing facilities at our premises which paves the way for us to provide the best possible industrial packaging.

Over half of the relevance use of industrial trays is from work-in-progress component across automobile, general industries, and electronic component manufacturers. Manufacturers of industrial trays have taken into consideration the requirement for protected transportation and using barrier material such as PVC, PET, PP and PS which has broadened the shelf-life of the product. Moreover, top producer of industrial trays is taking into consideration the aseptic manufacturing process which avoids crystallization and warrants the product lingers disinfected without the need for refrigeration, eventually increasing the products self-life.